Home / Capabilities / Assembly & finishing

Assembly & finishing

Painting & finishing

You expect your product to look its very best, and that’s what we deliver. We prep your product using our plastic bead booth and iron phosphate wash booth. Our paint booth accommodates items up to 25′ x 10′ x 10′ and uses high-quality Sherwin-Williams wet paint to give your product just the right finish.

Paint booth

The paint booth has been in operation for over 25 years and can paint any color or texture needed. We can accommodate product up to 25′ x 10′ x 10′.

- Wet paint process using Sherwin-Williams paint

- 20′ x 45′ paint booth

- 27′ x 34′ iron phosphate power wash station

- 21′ x 34′ plastic bead blasting booth

Black Oxide

We have a Birchwood Casey Black Oxide system for your black oxide needs.

In addition to our internal capabilities, we partner with outside sources for laser cutting, heat treating, grinding, anodizing and plating. Partnering with these quality resources allows us to focus on what we do best while still offering the advantages of one-stop parts sourcing that you demand.

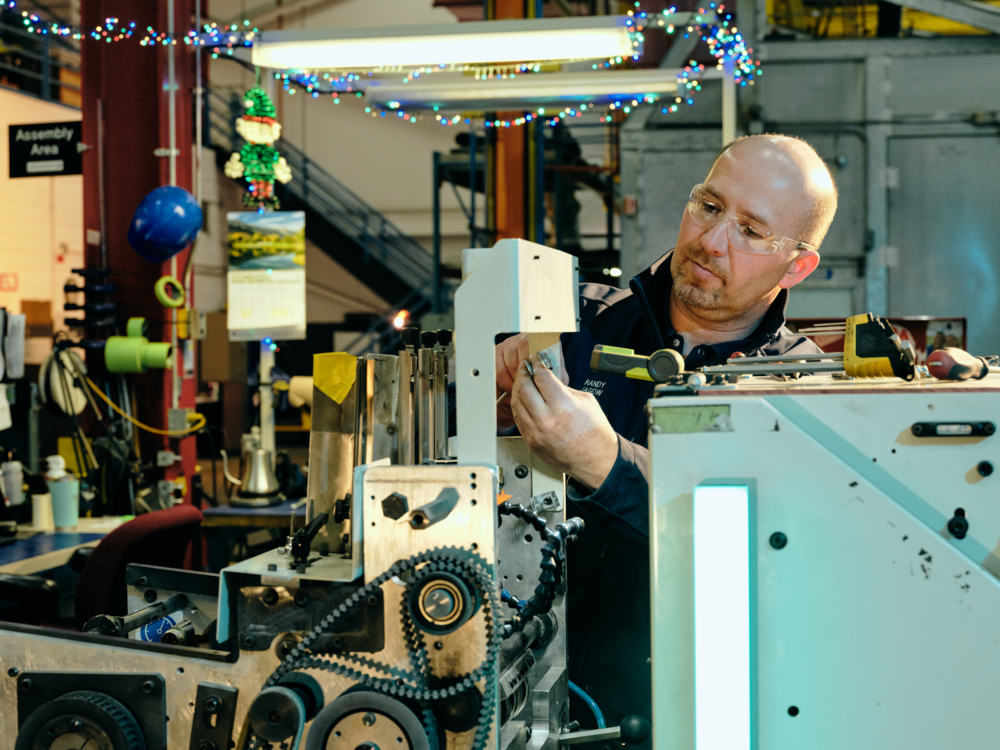

Assembly

Our Assembly department builds precision, close-tolerance, high-speed automation equipment. We build on a large surface plate and utilize our 8′ parallel to parallel and tram your equipment within one thousandth of an inch. Our fabrication shop, machine shop and paint booth all work with our assembly team for a one-stop shop experience.

- 8′ x 12′ surface plate

- 40′ wide x 20′ tall crane bay with 10-ton hoist

- Electrical and panel assembly

- 8′ parallel

- Level parallel and tram within .001″

Inspection

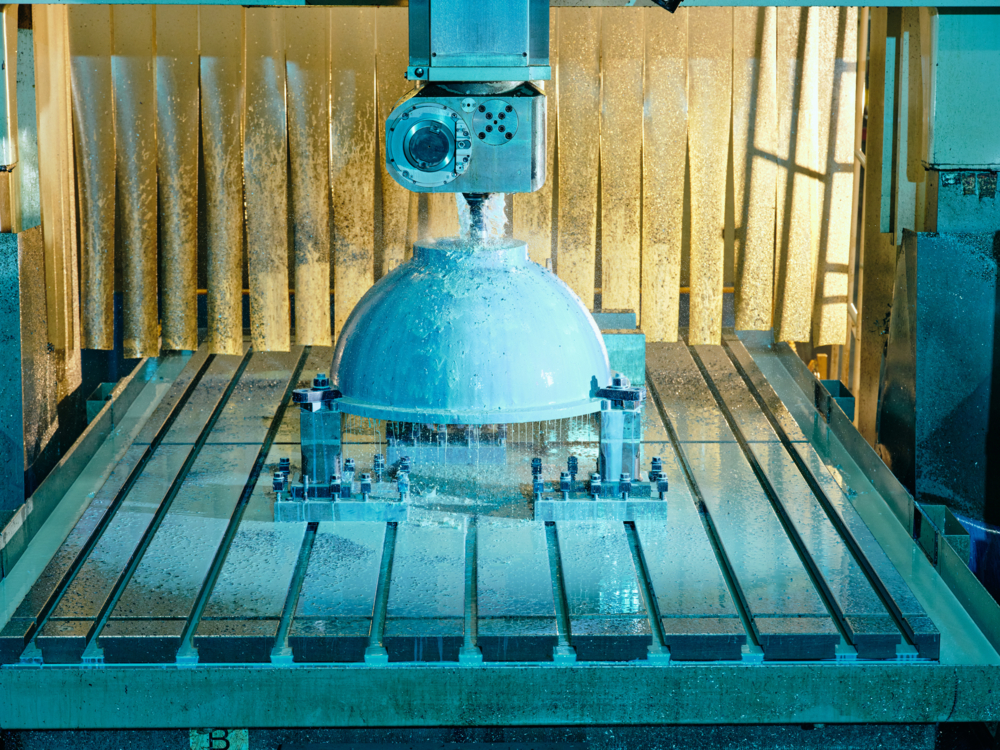

Our dedicated quality department follows a rigorous inspection program. From first-piece inspection through in-process and final inspection, we ensure your parts conform to all your requirements. All of our gages are routinely calibrated and replaced as needed. In addition, we can provide any required inspection documents you may need. Our CMM can provide the accuracy you need on your high-tolerance parts.

Zeiss Contura G2 Coordinate Measuring Machine

Our Zeiss CMM was purchased in 2013. The rotating sensor allows us to measure from 20,736 positions. The scanning sensor ensures we can measure every feature on your part.

- 700 x 1000 x 600 cm work area

- Vast XXT Scanning sensor

- Rotating Dynamic Sensor (180° with increments of 2.5°)

- Calypso Software with Curve

- Pro/E and STEP file conversion

- R&R fixture plate with clamp kit for custom part fixturing

Explore our other capabilities

Our fabrication job shop specializes in medium to large-sized structural steel welding.

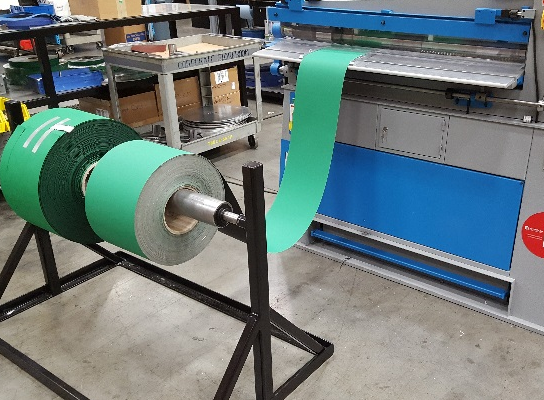

Our belt shop makes Forbo/Siegling, Nitta, and Habasit skived and finger spliced belts.